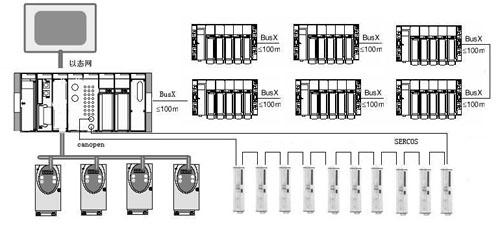

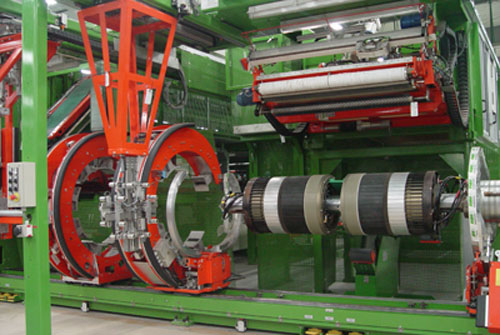

Molding machine electrical control system

Tire building machine electrical control system is a typical motion control, servo control system play a crucial role in the automation control.

In the tire building process, motion control several key technology to achieve:

1 Manual mode: in constant torque the operator manual mode of operation corresponding. (Manual mode of operation)

2, fixed-length control: the need to transport materials with fixed-length according to different specifications. (Such as the automatic feeding unit preparation)

3, the combination of axis control: that is, when part of the equipment movement requirements of other parts of sync with the movement speed or at a certain speed ratio matching. (Such as the material in the drum fit)

Interpolation control: that is, when each of the different parts of the equipment to complete different actions require time matching. (Such as a band strip winding)

In the tire building process, motion control several key technology to achieve:

1 Manual mode: in constant torque the operator manual mode of operation corresponding. (Manual mode of operation)

2, fixed-length control: the need to transport materials with fixed-length according to different specifications. (Such as the automatic feeding unit preparation)

3, the combination of axis control: that is, when part of the equipment movement requirements of other parts of sync with the movement speed or at a certain speed ratio matching. (Such as the material in the drum fit)

Interpolation control: that is, when each of the different parts of the equipment to complete different actions require time matching. (Such as a band strip winding)

The system uses multiple sets of servo controller to control the scene servo drives and lower motor:

1, manual control of the system we use servo controller control mode selection, is about to control mode selection to achieve MANUAL (manual) mode, in this mode, with the the PLC digital signal input module signal acquisition, in response to the operator operation. Operation involves FUNCTION CODE (control word) 2572 (mode selection). In this mode, we can complete the respective drum manually constant torque rotation, start and stop control and for manual control of the feeding rack feed.

2, the the automatic preparation process of the feed frame automatically fixed-length portion, we have adopted the INCR_MOVE (relative position) program, which in the current position on the basis of a further fixed length, the solution in the continuous production process Homing The problem, to be completed until Homing case of duplication of materials can be done precisely fixed length, the operation relates to the function code (control word) is 513 (the movement of the mode selection). In this mode, the servo motor will rotate at a certain speed to a specific location. This function of the servo system can be done to repeat, in accordance with a certain speed automatic fixed-length cutting of materials and transported to the preceding paragraph to be expected for the rack, waiting for the next fit of this process.

Synchronization fitting process, we have adopted a FollowingFunction (the Tracking axis) program, we built a new combination shaft, the combination of shaft by two or more axes, including a spindle and axis, when the spindle rotates, the axis followed by rotation in accordance with a certain speed ratio. Involved in the operation FUNCTION CODE (control word) 513 (sport mode selection) and 2114 (main modifications from the speed ratio between the axes). We apply the solution to stretching and accumulation of materials the automatic bonding material in the drum for the rack for feed rate and start-up time with the drum rotation does not match the molding machine.

4, since zero band in the bonding process requires a larger bonded joints, resulting in poor dynamic balance of the tire, the tire process mostly uses the band pieces to replace the zero with time, in the semi-steel building machine project, user requirements crowned under the different formulations of the different winding method, we use Co-ordinated Axes (interpolation). Create a new interpolation combined axis, in the application, we let crowned Article servo as spindle fit the drum from the shaft. Involved in the operation FUNCTION CODE (control word) is a 513 (sport mode selection). Refer to the program we have successfully resolved the the user requirements different crowned Article winding method and Guandai of spiraled process, crowned bars and drums action is relatively independent of the time required to match this difficulty.

1, manual control of the system we use servo controller control mode selection, is about to control mode selection to achieve MANUAL (manual) mode, in this mode, with the the PLC digital signal input module signal acquisition, in response to the operator operation. Operation involves FUNCTION CODE (control word) 2572 (mode selection). In this mode, we can complete the respective drum manually constant torque rotation, start and stop control and for manual control of the feeding rack feed.

2, the the automatic preparation process of the feed frame automatically fixed-length portion, we have adopted the INCR_MOVE (relative position) program, which in the current position on the basis of a further fixed length, the solution in the continuous production process Homing The problem, to be completed until Homing case of duplication of materials can be done precisely fixed length, the operation relates to the function code (control word) is 513 (the movement of the mode selection). In this mode, the servo motor will rotate at a certain speed to a specific location. This function of the servo system can be done to repeat, in accordance with a certain speed automatic fixed-length cutting of materials and transported to the preceding paragraph to be expected for the rack, waiting for the next fit of this process.

Synchronization fitting process, we have adopted a FollowingFunction (the Tracking axis) program, we built a new combination shaft, the combination of shaft by two or more axes, including a spindle and axis, when the spindle rotates, the axis followed by rotation in accordance with a certain speed ratio. Involved in the operation FUNCTION CODE (control word) 513 (sport mode selection) and 2114 (main modifications from the speed ratio between the axes). We apply the solution to stretching and accumulation of materials the automatic bonding material in the drum for the rack for feed rate and start-up time with the drum rotation does not match the molding machine.

4, since zero band in the bonding process requires a larger bonded joints, resulting in poor dynamic balance of the tire, the tire process mostly uses the band pieces to replace the zero with time, in the semi-steel building machine project, user requirements crowned under the different formulations of the different winding method, we use Co-ordinated Axes (interpolation). Create a new interpolation combined axis, in the application, we let crowned Article servo as spindle fit the drum from the shaft. Involved in the operation FUNCTION CODE (control word) is a 513 (sport mode selection). Refer to the program we have successfully resolved the the user requirements different crowned Article winding method and Guandai of spiraled process, crowned bars and drums action is relatively independent of the time required to match this difficulty.

Previous:

CNC laser marking

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Add.:Room 802, Block E, Power Creative Building, Shangdi East Road No. 1 , Haidian District, Beijing

Hotline:400-818-6918

Hotline:400-818-6918

Web:www.indiansky.cn

Web:www.indiansky.cn